Weigh-In-Motion (WIM)

- +971 50 9345504

- info@hbtrade.ae

- Dubai, U.A.E

Weigh-In-Motion (WIM)

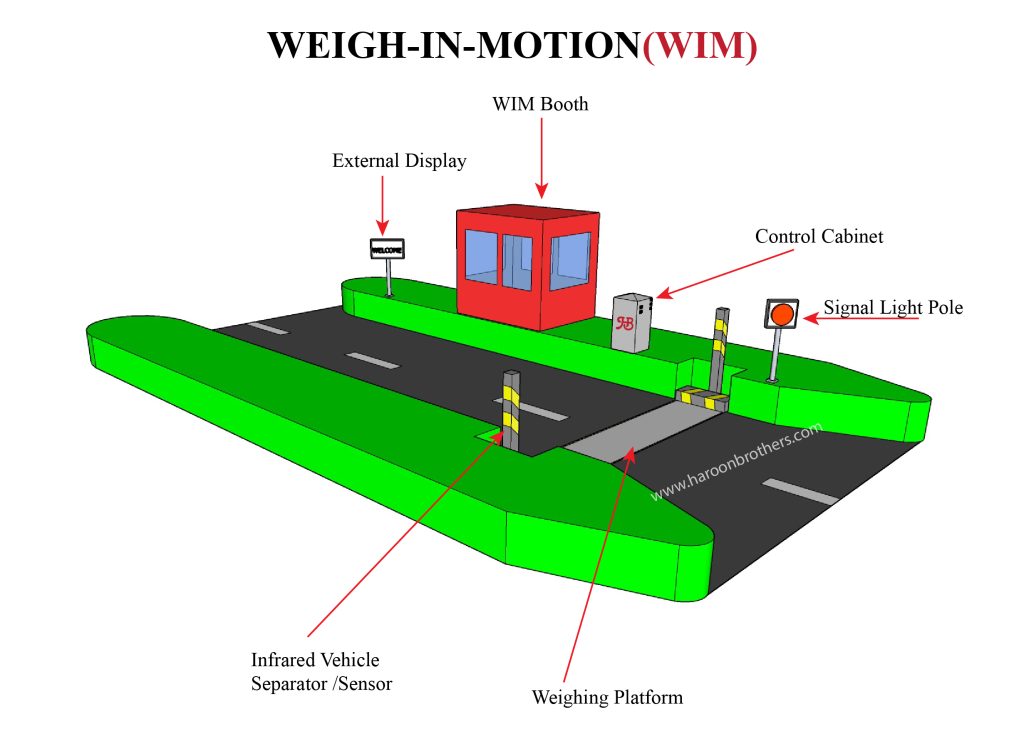

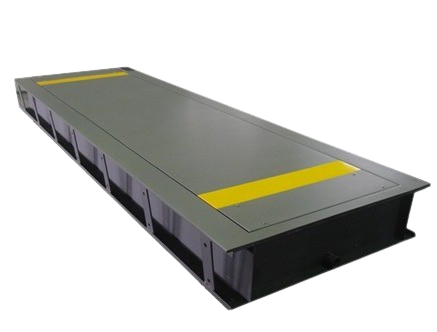

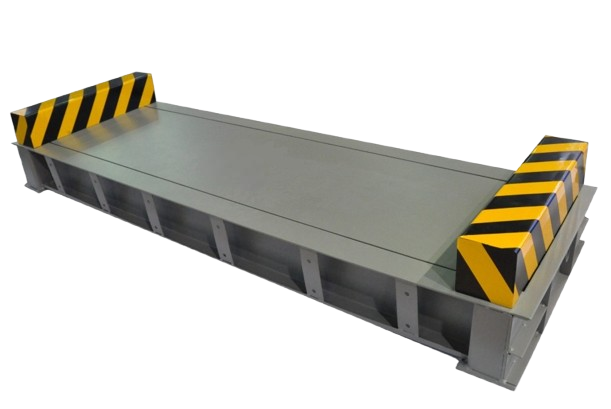

Weigh-in-Motion (WIM) systems measure Gross Vehicle Weights (GVW) and axle spaces of vehicles on highways at a free-flow traffic speed, and thus reduce traffic delays. The product designs special cover plate, it is very convenient for installment, repairment, maintance. The indicator could shows axis weight and the whole vehicle weight.

WiM systems can also help to minimize the risk of structural overloading bridges and roads, thereby increasing safety for all road users. By continuously monitoring the weight, it is also possible to reduce wear and tear on the road infrastructure.

The WIM systems measure commercial truck weight while the vehicle is moving at either highway speeds or slow speeds. The mainline data WIM systems are only used for data collection, and are not used directly for inspection or enforcement.

Weigh-In-Motion Software with ERP Integration – WimExpert

WimExpert is a high-performance weigh-in-motion (WIM) software designed to deliver accurate, real-time vehicle weight data without stopping traffic. Seamlessly integrated with your existing ERP systems, WimExpert enables efficient data management, compliance tracking, and automated reporting for logistics, transportation, infrastructure, and enforcement applications. Our advanced WIM system supports dynamic automated vehicle weighing, axle load detection, and overload control—ensuring faster throughput, improved safety, and reduced operational costs. With WimExpert, you gain a scalable, intelligent solution to optimize your weigh-in-motion operations from entry to enterprise.

Weigh-in-Motion (WIM) Services:

Our advanced Weigh-in-Motion (WIM) services provide accurate, real-time vehicle weight data without the need to stop traffic. Designed for highways, industrial sites, and logistics hubs, our WIM solutions enhance traffic flow, improve safety, and support regulatory compliance by automatically recording axle weights, gross vehicle weight, speed, and vehicle classification. Whether you’re managing road infrastructure, enforcing weight limits, or optimizing fleet operations, our high-precision WIM systems deliver reliable data to help reduce road wear and extend pavement life. Trust our expert team for professional WIM installation, calibration, and maintenance tailored to your specific needs. Optimize your operations with our scalable, cost-effective Weigh-in-Motion services today.

- Our Weigh In Motion System Offerings:

- Low-speed and high-speed WIM systems

- Axle load and gross weight measurement systems

- Portable and permanent WIM installations

- Integration with toll management and enforcement systems

- Real-time data monitoring and reporting software

- Calibration, testing, and certification services

- Annual maintenance contracts (AMC) and technical support

- Applications & Industries:

- Highways and Toll Plazas

- Transport and Logistics Companies

- Government and Law Enforcement Agencies

- Mining and Construction Sites

- Industrial Weigh Stations

- Ports and Cargo Terminals

Piezoelectric Weigh-In-Motion (WIM) systems

Piezoelectric Weigh-In-Motion (WIM) systems use piezoelectric sensors embedded in roadways to measure the weight of vehicles as they pass over at normal traffic speeds. These sensors generate electrical signals proportional to the force exerted by the vehicle’s tires, allowing real-time weight estimation without requiring the vehicle to stop.

Key Features of Piezoelectric WIM:

- High-Speed Weighing: Measures vehicle weight dynamically without disrupting traffic flow.

- Compact and Cost-Effective: Requires a relatively small installation footprint compared to traditional weighbridges.

- Durability: Piezoelectric sensors are highly durable and can withstand heavy traffic loads.

- Multi-Lane Operation: Can be installed across multiple lanes for large-scale traffic monitoring.

- Data Collection: Records axle load, gross vehicle weight (GVW), speed, and vehicle classification.